IPOL ILJIN Polycrystalline Diamond. (PCD Blank)

PCD - Polycrystalline Diamond, Polycrystalline diamond (PCD) tool materials typically provide abrasion resistance up to 500 times that of cemented carbide. In addition to superior abrasion resistance, PCD's high thermal conductivity allows heat to be transferred away from the cutting edge, preventing rapid tool wear.

PCD tools have replaced cemented carbide, ceramics and natural diamond in a range of high-performance applications including the turning, boring, milling, slotting, and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, composites, and engineered wood products.

The extended tool life and increased productivity provided by PCD tools often offset the higher initial cost by lowering the unit cost of parts produced. Useful tool life may be further extended through multiple re-sharpening.

PCD products are used extensively by the automotive, aerospace, electronics, woodworking, and optical industries. The application of certain advanced aerospace materials such as graphite-reinforced composites, is now practical because of manufacturing techniques using PCD tooling, PCD tools are advantageous for machining a wide variety of materials; however, PCD is not suitable for machining steels, irons, and other ferrous alloys due to chemical interaction between the tool and the work piece.

ILJIN PCD present as many grade and grain size to support most of customer work.

Grade CUF : Grain size 2µm. /Diamond 90% /Characteristics : Very good surface finishing.

Grade CFW : Grain size 4µm. /Diamond 90% /Characteristics : Good surface finishing.

Grade CM : Grain size 10µm. /Diamond 92% /Characteristics : General purposes.

Grade CMW : Grain size 10µm. /Diamond 90% /Characteristics : General purposes, Easy wire cutting and Good impact resistance.

Grade CCW : Grain size 25µm. /Diamond 90% /Characteristics : Good wear resistance with special binder and diamond bonding.

Grade CXL : Grain size 25µm. /Diamond 95% /Characteristics : Excellent wear resistance with strong diamond bonding.

Grade XUF II : Grain size <1µm. /Diamond 92% /Characteristics : Excellent impact resistance and Easier tool fabrication.

Grade CXL II : Grain size 40µm. /Diamond 95% /Characteristics : Specially designed for superior wear resistance.

Grade LCP : Grain size <1µm. /Diamond 40-70% /Characteristics : Easier tool fabrication than conventional PCD(almost same with PCBN).

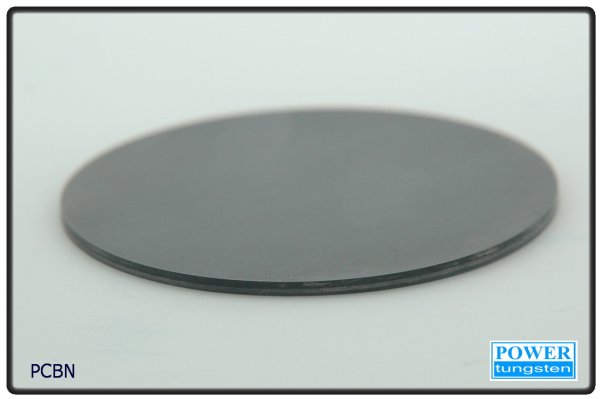

PCBN

IBON ILJIN Polycrystalline Cubic Boron Nitride.(PCBN)

Polycrystalline Cubic Boron Nitride (PCBN) tool materials represent a revolutionary advancement in cutting tool technology. For the manufacturer, the benefits are increased productivity, longer tool life, better surface finish, and the ability to hold closer tolerances. PCBN is used for machining a wide variety of ferrous materials.

PCBN provides increased productivity and cost savings over conventional carbide and ceramic tools. In many cases PCBN tools make it possible to machine materials where conventional tools have failed.

PCBN products are available in large full-round blanks and also offers pre-cut pieces to exact customer specifications.

For more information of PCD, PCBN, grade and stock, please check at our sales office.